Semi-autonomous Agricultural Robot

Semi-autonomous Agricultural Robot

Farming is crucial for life-sustaining and green life expansion. In agricultural fields, heavy machinery tools are used for plowing and performing agricultural tasks. However, this leads to high fuel expenses and multiple carbonic compound emissions. Supervised farming employs a number of employees to perform farming tasks and machinery controls. In this paper, a semi-autonomous robot is designed to endure the tasks set for employees and reduce carbon pollution. The robot is intended to navigate within the plots without supervision while performing seed sowing and fertilizing simultaneously.

1.011

Types

of crop agricultural robot system

Recently, there are several types of agricultural

robots with a set of definition and classification methods. The wide range of

researches carried out and technological studies targeting its specific tasks

in farming, livestock and aquaculture. Particularly, in crop farming

agricultural robot execute task by monitoring, crop managing, and controlling

the environment

2.0

Introduction

In recent years, the field of agriculture has

undergone significant advancements and transformations due to technological

innovations. One particularly promising innovation that has gained attention is

the emergence of semi-autonomous agricultural robots. These robots combine

cutting-edge robotics, artificial intelligence, and sensing technologies to

revolutionize farming practices, offering the potential for enhanced

efficiency, sustainability and productivity

Similarly, agribots, which are advance robotic systems

designed for agricultural applications, are semi-autonomous. These agribots are

capable of performing a wide range of agricultural tasks with minimal human

intervention. These intelligent robots have the capacity to navigate fields

independently, identify and handle crops, monitor plant health, precisely apply

fertilizers and pesticides, and carry out other essential agricultural

operations

In addition, semi-autonomous agricultural robots

utilize a wide array of components and technologies to ensure effective

execution of their tasks. As one of the components used in this project was the

Arduino mega, serving as a microcontroller board, plays a vital role in

overseeing and coordinating a wide array of functions and operations in these

robots. With its rich set of capabilities, including a multitude of digital and

analog input/output pins, ample memory, and powerful processing capabilities

Moreover, apart from Arduino Mega, Pololu Motor Driver

was also used. These drivers are electronic designed specifically to oversee

and control the movement and functionality of motors in robotics. These drivers

come equipped with features like bidirectional control, speed regulation, and

current limitation, making them excellently suited for managing and operating

motors utilized in agricultural robots

2.01

Agricultural

Robot Applications

2.011

1.3.1

Seed Sowing

The operations and methods for seed sowings

requires mechanical and electrical applications which is the core of any

robotic applications. Building a robot to perform a specific task in seed

sowing mechanism requires an electrical setup which composed of Arduino Mega

controller, servo motor, and the dc motors for robot movements, whereby the

mechanical application includes Rack and Pinion Mechanism and wheel mechanism

purposely for dropping seeds

3.0 Design Overview and Modelling

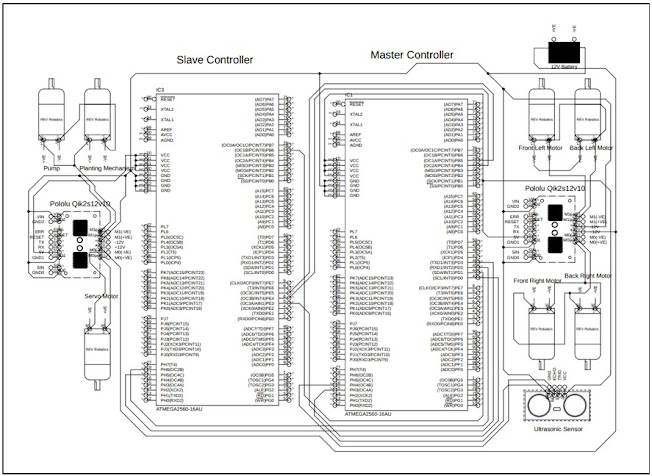

Figure 1: System

layout

The above figure expressed how

the system controls are laid out. The figure gives a complete overview of the

system applications and how the components are interfaced. It reflects the

Master controller and the Slave controller interfaces.

Figure 2: code

execution flow

The figure above laid out the code execution flow of each task in the written script. It shows how the Slave controller comprehends with the Master controller to execute the desired task. The two controllers were set-up separately where the Master controller continuously read from the ultrasonic sensor to update its navigation course. However, while navigating, interrupt signals of specific tasks are sent to the Slave controller to execute. The parallel execution of these tasks are timed by a single timer (Timer1) from the Master controller. This allows the synchronous execution between two controllers.

3.01 System Schematic

Figure 3:

Semi-autonomous Robot full schematic

Figure 1 above reflects the complete schematic used to

drive the semi-autonomous robot. The schematic expressed two form of

communication established by the Master to the Slave controller and both

controllers to the Qik2svs12 Pololu driver. The figure relays the communication

configuration made using external interrupts.

3.02 PCB Designing

The PCB should ensure secure connections and stable

transmissions between the Master controller, Slave controller and the two

Pololu motor drivers.

Figure 4: Designed

double layered PCB

The above figure laid out the PCB

design of the built schematic shown in figure 2. The configuration was not

suitable for a single layer PCB therefore assigned for a doubled layer

PCB. The PCB shows the footprints where

the component will be mounted and shouldered.

Figure 5: mechanical

structure modelling

The mechanical structure was designed to suit

the tasks needed for the robot to execute. The lower structure was designed

with steel iron to give the robot a reasonable weight. The control box houses

the control boards which was structured with aluminum frames not to exceed the

robot net load.

4.0 Controls and Mathematical formulations

4.01 Interrupt Communications

The interrupt

communication was established between the Master controller and the Slave

controller. The interrupt communication was a one-way communication, where each

main task was broken down into its minimum executable tasks. This subdivided

the planting mechanism process into three (3) subdivided tasks and the seed

dropper with another three subdivided tasks.

Table 1:

Interrupts to dedicated task

|

Main

Task |

id |

Sub-divided

Tasks |

|

Planting

Mechanism |

1. |

Drop Fork |

|

2. |

Brake

Fork |

|

|

3. |

Lift Fork |

|

|

Seed

Dropper Mechanism |

1. |

Shift

Left |

|

2. |

Brake

Servo |

|

|

3. |

Shift

Right |

As shown in

table 1 above, an interrupt was designated to each sub-divided tasks. This

makes up a total of six interrupts, while Arduino Mega has six external

interrupts by default.

Table 2:

designated interrupts

|

id |

Master

Controller |

Slave

Controller |

|

1 |

Digital

I/O 10 |

Interrupt

pin 2 |

|

2 |

Digital

I/O 11 |

Interrupt

pin 3 |

|

3 |

Digital

I/O 12 |

Interrupt

pin 20 |

|

4 |

Digital

I/O 9 |

Interrupt

pin 19 |

|

5 |

Digital

I/O 8 |

Interrupt

pin 18 |

|

6 |

Digital

I/O 5 |

Interrupt

pin 21 |

The above table lists the selected interrupts and where it

is attached to from the Master controller. As realized by the table, the Master

controller, possess no interrupt pin for this communication, however, trigging

interrupts for the Slave controller.

4.02 Serial Communication

Serial communication was established between the

Qik2svs12 Pololu driver and the Master controller. The serial communication pin

Rx and Tx were adopted to handle communication between the controllers and the

Qik2svs12 Pololu driver. Serial pin Tx of the Master controller was connected

to serial pin Rx of the Qik2svs12 Pololu driver to secure transmission from

Master to Qik2svs12 Pololu driver. Serial pin Tx of the Qik2svs12 Pololu driver

was also jumped to the serial pin Rx of the Master controller to allow

inspection of the motor from the Master controller side.

Table 3:

Arduino Mega 2560 to Qik2svs12 Pololu dual driver pin to pin connections

|

id |

Arduino

Mega 2560 |

Qik2svs12

Pololu |

|

1 |

Common GND |

Common GND |

|

2 |

5V Vin |

5V Output |

|

3 |

Serial

Communication Pin Rx – 18 |

Serial

Communication Pin Tx |

|

4 |

Serial

Communication Pin Tx – 19 |

Serial

Communication Pin Rx |

The following interface were made between the Arduino

Mega 2560 and the Qir2svs12 Pololu dual motor driver. This connection is to

establish serial communication; a few conditions are considered. It assumes

that the jumper is placed at a chosen baud rate and not the Demo mode pins. It

also assumes that the Serial baud rate of the of the Arduino Mega is set to the

jumped baud rate of the Pololu driver.

5.0 Results

5.01 Precision & Accuracy

Figure 6: system

navigation accuracy

The robot was built with a single

ultrasonic sensor for navigation purposes. As seen in the plot above, the

sensor’s range is constrained from 3cm to 50cm where out of this range, the

ultrasonic sensor starts to lose its accuracy. This graph reflects the operating range of the ultrasonic

sensor where the best operating range was chosen. With this fact, the

ultrasonic sensor was

mounted at 17cm away from its

operating point. The sensor starts to read from the at 17cm by

subtracting the reading distance with 17cm. This initialize the sensor at 0cm

at the initial point of its working range.

Figure 7: system

error plot

The system error plot was made to

create a visual on the ranges and the error it poses. As seen in the above

figure, from 0 to 3cm, the sensor was inconclusive with imprecise responses.

The error bounces around 0 to 0.5cm until it reaches 50cm range. At 50cm range,

the error starts to increase and continuously does as distance is increased.

5.01 Spacing

In this context, the spacing is defined by the

robot consistency and synchronous of movement. If too delay is encounter, the

desired spacing will either be exceeded or not satisfied.

Figure 8: figure expressing the actual space

and the space ran by robot

The figure above was obtained from a test made

for the robot to run at specified spacing. The robot was made to run at an

interval of 34s and 2s cm. The interval defines the actual minimum spacing of

corn seeds. If a closer look is made on the plot, errors could be identified at

some intervals.

Figure 9: plot of system spacing error

Figure 9

above plots the spacing error which is the difference of the actual spacing the

robot should run and the measured spacing it actually ran. It can be observed

that the error does not increase continually, it fluctuates but remains at

certain range. The maximum error collected in this sample was 2.1cm while the

minimum error was 0.2cm.

Comments

Post a Comment